新聞資訊

Address: Shenzhen City, Baoan District Xixiang Shu Donghua third industrial zone B building 7 floor

Telephone: 0755-2908-2001/2003

Fax: 0755-2908-2001

Q Q:540775041

Mailbox: 540775041@qq.com

URL: chaohongfuzhuang.cn

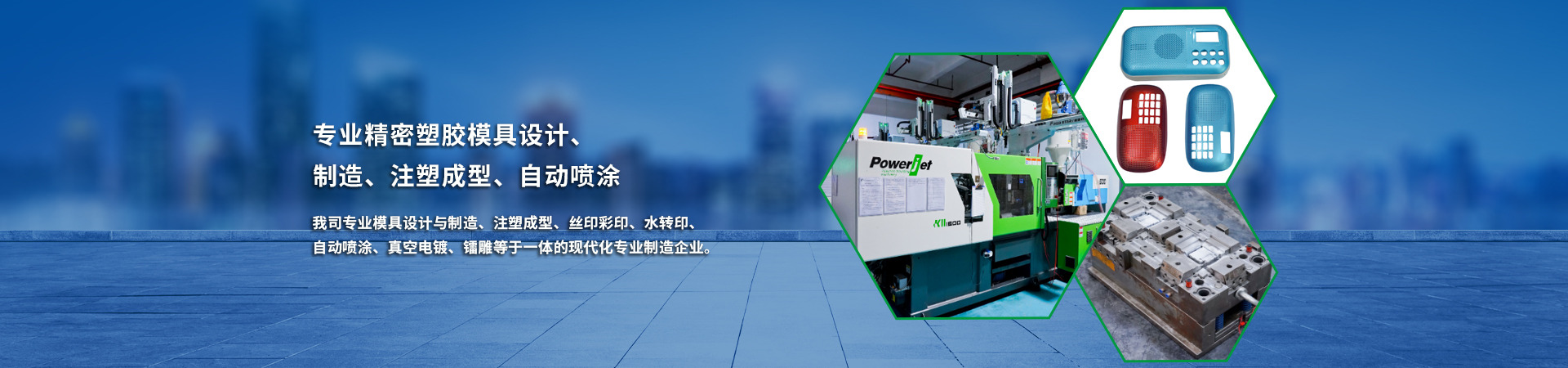

The injection mold has the following basic parts: molding parts system, exhaust system, pouring system, temperature regulating system, demoulding system and guiding positioning system.

What role do they play respectively?

1, forming parts, which constitute the mold cavity parts, mainly used to determine the shape and size of plastic parts, such as the convex mold determines the internal shape of the plastic parts, and the concave mold determines the shape of the plastic parts.

2, when the melt into the high speed exhaust structure in injection mold cavity, the cavity in the air to be exhausted, and the high temperature plastic will emit some gases, these gases are needed quickly, in order to avoid forming defects, the injection mold for the gas discharge and the design of the structure of every kind of exhaust.

3, pouring system, which is the injection of plastic melt into the closed cavity, has important influence on the flow characteristics and injection molding quality of melt filling process

4, temperature control system, because of the different properties of plastic, injection molding on the mold temperature requirements are different, therefore, the temperature control system is required to adjust the temperature of the mold. The cooling of the mold usually depends on the cooling water in the cooling water channel, and the heating of the mold depends on the heating element in the mold.

5. The release of the plastic part of the demoulding mechanism is finished by the demoulding mechanism. The release mechanism in Fig. 4-1 is composed of a push rod, a bottom plate 8 and a push rod 11, and the bottom plate 9 and the material pulling rod 10 are combined.

6 molmerged steering mechanism used to ensure that the movable mould and the fixed mould, among other parts or in the mold to ensure accurate on the plastic parts, the shape and size precision, and avoid all kinds of mould components of collision and interference.

7, type and core pulling mechanism when the plastic parts with concave side or side hole, in the mold plastic parts to launch before, must put the concave side or the side hole forming the flap combined module or the lateral core from the part and the lateral type prolapse or lateral core pulling mechanism is to achieve this function set a lateral movement mechanism.

8. Parts such as supporting parts are used to install, fix or support molding parts, and the supporting components are assembled together to form the basic framework of the injection mold.

Shenzhen City Tengfei and plastic products Co., Ltd. was founded in 2008, professional mold design and manufacturing, injection molding processing, automatic spraying, vacuum plating, and all kinds of screen printing, UV printing, printing, color printing, water transfer printing, laser engraving, bronzing in one of the industrial company.

Tel: 0755-2908-2001 mail box: 540775041@qq.com website: chaohongfuzhuang.cn

755-2908-2001

755-2908-2001